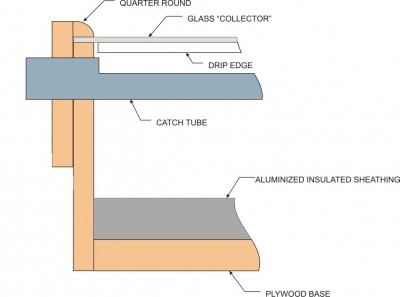

The author’s solar still, with one pan in it. The still actually has room for two of these. Note that the glass top is at an angle, allowing the water to flow down to the catch tube.

Everyone agrees that water is needed for survival and articles abound for how to find water and purify it for drinking. But all those articles have one thing in common: They are talking about purifying water from biological hazards.

Normally, the biggest hazards we face from drinking water are microorganisms: bacteria, protozoa and other parasites which can enter our system and make us quite sick. These are a legitimate concern and one that every survivalist must take into account. A case of dysentery can kill you, especially if you are already weakened or injured.

While those biological hazards are important, they aren’t the only thing we can find in our drinking water. Chemicals, radiation, salt and minerals can all be there as well. While a fine-enough filter can get rid of biological hazards, particulate minerals and radiation, it can’t do a thing about salt or chemicals. Activated charcoal will help some with some types of chemicals, but the only sure way to get rid of those is through distillation.

Distillation is a simple process, although it can be difficult to accomplish in quantity. It consists of heating the water to the point where it evaporates quickly or steam forms. Then, that water vapor is captured and cooled, allowing it to condense back to water.

The really great thing about distillation is that nothing else evaporates with the water. The only chemicals that could evaporate with it are those that have a lower vapor point than water does. There aren’t too many chemicals normally found in a liquid state at typical ambient temperatures, which also have a lower vapor point than water does. Alcohol is one of the few.

The problem with distillation is that it is a slow process, which means that heat has to be applied to the water for a long time, so that it can evaporate and be captured. In a crisis situation, fuel might be scarce, making the process of distilling water rather expensive, from a resources point of view. This can be solved by harnessing the power of the sun in a solar still.

When most people talk about a solar still, they are talking about a covered hole in the ground, which is used to purify water in an emergency situation, typically in a desert or other arid place. That’s not what I’m talking about here. I’m talking about building a permanent solar still, which can be used to distill water on a constant basis.

A solar still, like many solar collector devices, consists of a glass-covered box, which is painted on the inside. A pan of water is placed inside and the device is placed in the sun. Sunlight enters the box and heats the water, promoting evaporation. When the water vapor hits the glass, it condenses on it, running down the glass to a catch tube.

Directions to Make the Solar Still

To make a solar still of this type, you’ll need to make a box out of plywood. You can’t see it well in the picture, but the white line at the back of the still is a door, which flips down to allow the water pans to be placed inside it. For water pans, I used two large rectangular Pyrex dishes. To accommodate them, the inside dimensions of the box are 19 inches wide by 23 inches long. I was careful about this measurement, as glass commonly comes in pieces that are 24, 36 and 48 inches. Had I made the box just a little bit bigger, I would have needed to buy a 36-inch piece of glass and waste most of it.

Ultra Efficient Water Filter Fits In Your Pocket!

The front of the box (the end with the catch tube) is 6 inches tall, while the back of the box is 9-1/2 inches tall. This allows sufficient slope to cause the condensed water to run down to the catch tube (more on that in a moment). The sides of the box are constructed of two layers of half-inch plywood, while the bottom is of 3/4-inch plywood. That gave me sufficient thickness at the bottom to make it easy to connect it together.

The sides and ends of the box are double thickness, providing a notch at the top for the glass “collector” to mount into. The outer piece of plywood should stick up half an inch above the inner one. I purposely made the outer piece of plywood “short” so that it would provide a ready handle for carrying and moving the solar still.

When inserting the glass, it should be held in place by silicone caulk. Quarter round or base shoe can be placed above it to finish off the box. Be careful when nailing the quarter round in place, so as to not hit the glass with the nail or hammer.

A piece of three-fourths or one-inch thick aluminized insulated sheathing needs to be cut to fit the inside of the box and placed in the bottom, aluminum side up. The aluminum surface of this piece of sheathing and the entire inside of the box should be painted flat black to absorb as much light as possible, converting it to heat. The aluminum coating on the sheathing will readily absorb and transfer this heat to the Pyrex baking dishes. Pyrex is used to reduce the risk of breakage.

The hardest and most important part of the design is the drip edge and catch tube. I used a rubber door seal (without the metal backer) as the drip edge. You can glue it in place with silicone caulk, allowing the caulk to dry fully before turning the glass over. Be sure to fill the “uphill” side, where the drip edge attaches to the glass, to provide a smooth transition for the water drops to flow down. The drip edge needs to be located directly above the center of the catch tube. So, you will need to place the glass on the box, mark it for the drip edge and then remove it to install the drip edge to the glass, before installing the glass into the solar still.

The catch tube is a piece of half-inch PVC pipe. The outside diameter of half-inch schedule 40 PVC is slightly less than seven-eighths of an inch, making it easy to put a hole through the side of the still for it with a spade bit or forstner bit. Drill partially through the opposite wall of the still’s box from the inside, so that there is a pocket for the catch tube to sit into. Glue it into this partial hole with silicone caulk to both seal the wood and hold the drip tube in place.

To make the catch tube, make two lengthwise cuts in a piece of half-inch PVC pipe, about 120 degrees apart. It is easier to do this if you make the cuts too long, and then cut the tube to length. The cut-out portion of the tube should span the entire still, with the full tube starting where it goes through the side of the box.

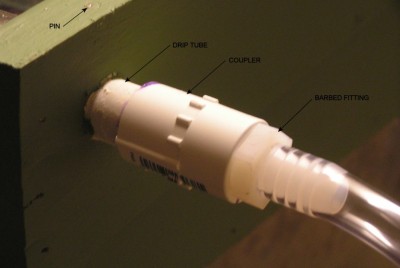

The drip tube should be held in place by a pin at the outlet end. This can be a small nail. Just drill a hole down through the side of the still’s box and insert the pin to keep the tube from pulling out. A half-inch slip to half-inch threaded coupler is attached to the end of the catch tube, with a barbed fitting connected to it. A short piece of tubing is connected to this fitting.

Using the Solar Still

The solar still can be used all day long, even if it is slightly overcast. If it is properly sealed with paint, it can be left out even in a rainstorm. To use it, place the still in a place where it will receive good sunlight, without any possibility of it being shaded. Point it toward the south so that it can capture the most sunlight. Place a water jug or food-grade five-gallon bucket so that the drip tube will empty into the bucket or jug.

Fill both Pyrex pans with water and place them inside the still, ensuring that the door closes securely, without any air gaps. While the solar still is not fully airtight, you don’t want the water vapor escaping into the atmosphere. Leave the solar still and come back later to collect your water.

You can use literally any water with a solar still. It does not need to be pre-filtered in any way. Debris left in the water will stay in the Pyrex pans, while the clean water will be distilled out. If the water used is dirty, full of debris and silt, you will want to rinse out the Pyrex pans when it is time to refill them.

Off The Grid News Better Ideas For Off The Grid Living

Off The Grid News Better Ideas For Off The Grid Living