You’ve probably seen one of those ads selling a book about how to make a “ghost gun” at some point in time. What’s a ghost gun? It’s a gun that isn’t on the books anywhere. It’s not on the books because it was not manufactured by any licensed manufacturer. Therefore, the gun doesn’t have a serial number — and there’s no record of its sale.

This almost sounds illegal, but I assure you it’s not. I’m not talking about buying a gun that’s manufactured in a secret facility somewhere, where they don’t follow the law. Nor am I talking about buying a gun from which someone has removed the serial number. What I’m talking about is a perfectly legal way in which you can make your own gun, specifically an AR-15, which is one of the most popular guns on the market.

To understand this, you have to understand a little about firearms manufacturing law. According to the law, it is necessary to identify one part of the gun as actually being “the gun.” The rest of it is just parts. The reason for this is that the part which is identified as the gun receives the serial number. For most guns, the part that is so identified is the gun’s frame. In the case of the AR-15, that’s the lower receiver.

The serial number doesn’t legally have to be added to the gun frame (or lower receiver) until the gun is at least 80 percent completed.

How To Defend Yourself And Your Family Against The New Breed Of Lowlife Criminal Scum

If you buy an AR-15 lower receiver that’s gone through the manufacturing process up to that 80 percent point, but no further, you can buy it without a serial number. You can then finish manufacturing it yourself and end up with an off-the-books AR-15.

This is totally legal, as long as you are making it for your personal use. You cannot give or sell that gun to anyone — not even a family member. You also have to do all the work on it yourself. If you pay someone to do any part of the work, you are then an unlicensed firearms manufacturer and subject to prosecution under the law. To put a point on that, I realized it meant it would be illegal for me to take my lower receiver to a shop to have it anodized (the normal finish for the part) or to take it for laser engraving (the normal way of putting on a manufacturer’s name and serial number).

Making Your AR-15 Lower Receiver

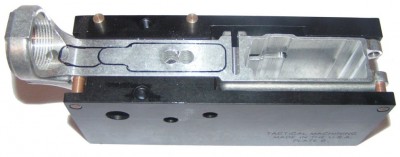

AR-15 Lower receiver casting in the template, with the top plate removed. The outlined area is what has to be cut out for the trigger group pocket. The two visible holes in the cutout are for the trigger. In addition, there are three holes in the sides of the template, which need to be drilled out.

There are a number of sources which you can find online for these 80 percent complete AR-15 lower receivers. They are available in either cast aluminum or injection-molded polymer. Some of the companies also supply the aluminum casting already anodized (for those who don’t want to have to paint them).

The advantage of the polymer AR-15 lower receiver is that it’s easier to machine. However, that ease also means it’s easier to mess it up. I messed up the first polymer AR-15 lower receiver that I tried. They are also weaker than aluminum lower receivers. While they are strong enough for firing, if you drop the gun in a way that the lower receiver strikes something hard, it will probably break.

Finishing the AR-15 lower receiver requires milling out the material in the trigger group well and drilling a few holes. All of the other, more complicated machining is already done. Of course, since the trigger group well isn’t machined out, the part can’t be a gun, as it’s impossible to assemble the trigger group and make it into a functional firearm.

To do this work, you’ll need a few tools. In addition to the lower receiver casting, you will need to buy a template. The companies who sell the castings also sell the template. This template allows you to accurately cut out the necessary material from the lower receiver casting, in order to make the trigger group pocket, as well as providing precise location of the holes you need to drill.

How To Hide Your Guns, And Other Off-Grid Caches…

The absolute best way to do this is on a mill. That’s a little expensive for most people’s budgets. However, you can do a fairly good job of it with a drill press and a milling vice (otherwise known as an X-Y table). This allows you to precisely position the casting and move it in a straight line for cutting with an end mill held in the drill press’ chuck. You can’t use a drill bit for the final cutting, but you can use drill bits to drill a series of holes to take out a large part of the material. About the smallest drill press that can be used for this effectively is a 14-inch benchtop model.

Cutting the pocket has to be fairly precise, but it is actually the least precise part of machining a lower receiver. You will need some dial calipers to check your dimensions, because the width of the cutout is important, as well as the depth.

Finishing the AR-15

Once the lower receiver is machined, you’re ready to start building your AR-15. There is no law that requires that you put manufacturer’s information and a serial number on it, but I would recommend that for identification purposes and so that your rifle doesn’t stand out obviously as not having one.

To finish out the lower receiver, you’ll need the parts for the trigger group, the buffer and tube, and the stock. These parts can be purchased individually or in a kit. Buying them in a kit is usually easier. A special tool is required for installing the buffer tube. If you are going to build your AR-15’s upper, the barrel wrench (another special tool) will usually include this wrench, but if not, you’ll need to buy a buffer tube wrench. They are not very expensive.

You can either build your upper receiver and barrel or buy one that is already assembled. A number of companies sell upper receivers and barrels that are already assembled, for installation on your own lower assembly. This saves a lot of work and can also save money over the individual cost of the parts.

Speaking of cost, don’t think that you’re going to save any money building an AR-15 this way. Generally speaking, the cost of the casting is more than buying a finished AR-15 lower receiver. Plus, you have to add the cost of the template and an end mill. If you don’t already have a drill press and a milling vice, you’ll have to add those costs as well.

However, although you many not save any money, building your own AR-15 in this manner is still a great idea, can be rewarding – and is totally off-the-books.

What are your tips for making an off-the-books AR-15? Leave them in the section below:

Off The Grid News Better Ideas For Off The Grid Living

Off The Grid News Better Ideas For Off The Grid Living