Making hard cheeses is no more difficult than making soft cheese. The curd-making, which is the soft cheese-making stage, can be considered the most difficult part of the whole process. For hard cheese, you have just a few minutes of work followed by several hours, days or weeks of wait time.

Before getting started making your own hard cheeses from milk, you will need some extra equipment. This is more specialized equipment so you will need to purchase some or all of it from a cheese-making supplier.

Supplies

- Cheese Mold and Press. These units can be rather expensive but if you are going to make hard cheeses often, it is an excellent investment.

- Your choice of how to age your cheese. There are several ways to age and store your cheeses. Depending on which process you choose, your supplies will vary: 1) Cheese salt – this is used for those cheeses that are rubbed with salt or brined prior to aging. 2) Cheesecloth, butter muslin and your choice of fat – these items are used in the wrapping of cheese for aging and storage.

- Waxed paper

- Plastic wrap

- Aluminum foil

- A place to age your cheese.

- A place to store your cheese.

So let’s take the plunge into making hard cheeses! The following instructions will walk you through the process of pressing your cheese. The only differences you will find on the specific cheese-making recipes will be the different pressures required for that specific cheese type or if you are making a “blue,” or mold-veined, cheese. The latter will include directions for adding the proper mold culture to create the veined aspect of that cheese.

“Cheesemaking”: The Book You Need To Make Every Type You Crave

Pressing Curds into Cheese

1. Line the mold with damp cheesecloth.

2. Fill the cloth-lined mold carefully with cheese curds. (Learn how to make cheese curds here.) Pull up on the damp cloth to eliminate unnecessary bunches or folds. Press the curds down to fill in any gaps and fill to the top of the mold.

3. Cover the top of the curds with the extra cloth. Avoid making folds that might indent the top of your cheese. You can trim off the excess fabric so that it only overlaps by one-fourth an inch or so.

4. Place the plastic or steel disc that comes with the press into the top of the mold. It should move easily inside the mold without leaving an excessive gap around the edge. It is called the “follower.”

5. Apply pressure according to the recipe’s directions for the time specified in the recipe. The whey will ooze out of the curds as the pressure is held on the mold. Use a bowl or other container to catch the liquid.

- Always follow the directions for the specific cheese recipe you are using. However, if the recipe doesn’t tell you how long to press the cheese, how many times to flip it or how much pressure to use, then we use these rules:

- Press for one hour at five pounds of pressure.

- Flip the cheese, replace in the mold, press for eight to 12 hours at 20 pounds of pressure.

- Flip once more, replace in the mold, press for an additional eight to 10 hours at 20 pounds of pressure.

6. When you have followed the directions on pressing your cheese, remove the wheel from the mold. Gently unwrap the cloth from around the wheel and place it on a rack in a cool, dark place away from drafts to let it air dry. Your recipe will tell you how long to let it air dry.

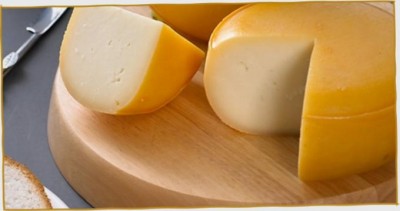

Congratulations! You have made your first wheel of hard cheese. When you have all of the curds pressed into wheels and they have air dried according to the amount of time specified in your recipe, you are ready to move on to the aging process.

There are three basic ways to age your cheese. However, all of these ways will occur between 55 and 65 degrees with 70 percent humidity. I know what you’re saying; that is inside the “danger zone” for bacteria production. However, that is part of what we want to happen. You introduced bacteria into your curds when you added cultures to your milk at the beginning of the process. You want those to grow and develop so that your cheese will have a more full-bodied flavor. One thing you need to remember: Aging is not storing. We’ll discuss storage a little later.

Aging Your Cheese

-

Salt-rubbed. This is the simplest process. It involves sprinkling salt over every inch of the cheese and gently rubbing the salt into the outside layer. The wheel is left in a draft-free, dim area and retreated according to the specific recipe.

- Some recipes for cheese making call for the green wheel to be soaked in brine. This process is used for cheeses with a short aging period. This is why you brine:

- Brining inhibits the growth of bad bacteria on the outside of the cheese when it is brought out of the brine for further aging.

- Brining helps develop the rind of the cheese and contributes to the overall flavor of the result.

- Depending on the cheese, you will use a light, medium or fully saturated brine. Consult your recipe for directions.

- Keep your brine around 55 degrees if you wish to store it for reuse. If the brine stays at or above 60 degrees for an extended length of time, you should toss it and start over.

- Brine can be used in one of three ways: soaking, spraying or washing.

Discover How To Make Just About Anything … From Scratch!

- Wrapping or Bandaging. This process is used to assist in rind formation and aids in developing a full-flavor profile and texture in hard cheese. The process of bandaging hard cheeses requires a somewhat more detailed procedure.

- Here’s what you need for wrapping your cheese.

- Cheesecloth

- Butter muslin

- 1 cup of butter, lard, oil or other fat of your choice.

- Lay out 4 layers of cheesecloth. Set the cheese on top of the cloth. Cutting through all four layers, cut circles about 1 and a half inches larger than the wheel of cheese. You will use two layers of cheesecloth for each flat side of your wheel.

- Cut out two, long strips of muslin just a little wider than your wheel of cheese. The strips should be long enough to wrap around the edge of the wheel with just a little overlap.

- Rub one flat side of your cheese with some of the fat with gentle circular motions. When you have an even layer of fat on the cheese, place one layer of cheesecloth on that side and press it carefully into place. Repeat the addition of fat to the cloth and add the second layer of cheesecloth to that side. Perform the same process on the other flat side of the cheese until all cheesecloth has been used. Rub the fat into the edge of the raw cheese until there is an even layer so that you can fold up the excess cheesecloth. Repeat until you have folded the second layer of cheesecloth against the edge and then continue adding fat to the edge until there is another even coating to hold the butter muslin strip in place.

- When the cheese is completely covered, set it aside in a temperature- and humidity-controlled space. This should be away from drafts and sunlight for the indicated aging period.

- Here’s what you need for wrapping your cheese.

Once you have your cheese prepared for aging or ripening, you have to decide just where in your home you can do this. Hopefully you have researched your new hobby and prepared a place for the tasty result you are looking to produce. As long as you have a place that is warm enough, dark, humid and completely clean, you have the perfect place to ripen your cheese. It can be a closet, a cellar or basement, a dedicated refrigerator, even a hole in the ground so long as it remains above 55 degrees and below about 70 degrees to promote the proper bacterial or mold growth required for the cheese.

Aging cheese is the hardest part of the whole cheese-making process. No one is perfect and mistakes can happen, so don’t be discouraged if you find portions of your batch have not turned out as you thought they would. There are many factors associated with making cheese and whether or not it turns out properly:

- The type of cheese being made

- The addition of mold powder

- Acidity levels (pH)

- Moisture content

- Salt content

- Size and shape of your particular cheese

There is no “magic’ number for temperature, humidity or time and no set procedure to assure the perfect wheel of cheese. If you stick with one particular type of cheese, you will begin to get the feel for what works and what doesn’t when producing that cheese. As with many other homesteading crafts, practice makes perfect. like cheese-making, practice makes perfect.

Every Year Gardeners Make This Avoidable Mistake — But You Don’t Have To. Read More Here.

Off The Grid News Better Ideas For Off The Grid Living

Off The Grid News Better Ideas For Off The Grid Living