image credit energyblog.nationalgeographic.com

In olden times, wells were dug with a pick and shovel, with a lot of backbreaking work. Depending upon the location, the well might have to be dug quite deep to provide enough water. That much backbreaking work wasn’t something that anyone would want to do, even though it was a necessity.

Today, wells are usually drilled. A well drilling rig is essentially the same thing that they use when drilling for oil, only a lot smaller. A drill bit is lowered into the well hole on the end of a pipe. The motor, which is above ground, turns the pipe, driving the drill bit. Water is pumped into the hole, in order to flush out the dirt and sand that is being cut loose by the drill bit, bringing it up to the surface for disposal.

The only problem with that system is cost. If you are thinking about having a well drilled on your property, you’d better have some deep pockets. I was going to have one drilled at my home, until I found out the price was going to be over $5,000. Needless to say, I wasn’t happy.

The laws vary from state to state, but in much of the country, you can still put in your own well. Some states may require a permit, but usually if you’re doing the work yourself, there is no permit requirement. Just make sure that you aren’t paying a buddy to help you, or he would be considered a contractor and fined for working without a license or permit.

While you can put in a well just about any place, you should stay a minimum of 50 feet (or more) away from any septic tank or field lines. Groundwater is common in much of the country, and you can contaminate any groundwater source with an improperly located well (and contaminate any other well that is tapping into the same groundwater source). North Carolina has put together some good information on well drilling that you can find here. Minnesota has put together an information packet for well setbacks from different types of septic systems. Depending on your area, this may be different for your state. Contact your county extension service to see if your state has specific guidelines for well setbacks and adhere to those numbers. The last thing you want is a contaminated water source.

Water is most commonly found in sandy layers, with the best water in sandy layers that are trapped between layers of coal. The ground beneath us consists of different layers of material, which include loam, dirt, sand, rock, clay, and coal. The secret to having a successful well is going down deep enough to find one of those sandy layers, and then finishing off the well. Unless you’re living in a very arid area, you can probably start finding water as little as 20 feet below the surface.

As a well goes down, it will probably pass through several sandy layers, each of which is totally separate from the others. That means that the water coming from each of those layers will be different, with different mineral contents and different salt levels. While you can probably get water from a shallow well, most of the time you will get better water from a deep one. Shallow wells are those that are less than 30 feet deep. Deep wells are typically more than 70 feet deep and can be several hundreds of feet deep.

Ultra Efficient Water Filter Fits In Your Pocket!

I suppose if your groundwater is shallow enough, you could still hand dig a well with a shovel and pick. But for most of us, we’re going to need to go deeper than practical to dig a well. We’re going to need to use some more complicated methods.

Driving a Well

The fastest and easiest way to put in a shallow well is to put in a driven well. This is just what it sounds like, a well that is pounded into the ground, just as a nail is pounded into a piece of wood. This requires using a well point, which is a combination of a well screen with a hardened point attached to it.

This tends to work the best in soft soil. If you have high clay content in your soil, then it is extremely hard to put in a driven well. Of course, that high clay content also makes it harder to drill a well.

Before the drill point is used, a pilot hole about two feet deep needs to be dug into the ground with a post-hole digger. A threaded cap is screwed onto the end of the well point, without tightening it, to protect the threads on the end of the pipe. The drill point can be placed in this hole and driven into the ground with a sledge hammer. Some people prefer a “slam hammer” of the type that is used for putting in metal fence posts.

When there is only about 10 inches of pipe sticking above the ground, it’s time to add a section of pipe to the drill point. Remove the cap and install an internally threaded coupling. A good Teflon pipe joint compound must be applied to the threads to ensure that the well casing seals properly. Add pipe in five-foot sections, as any longer will put the top too high to be able to drive it. Don’t forget to put the cap onto the new section of pipe to protect the threads.

You can tell when you reach the water table, because you’ll hear a hollow “bong” when you strike the pipe. You can check how far into the water table you are by removing the cap off of the pipe and dropping a weighted string into the pipe. When it hits bottom, draw it back up and see how much of the string is wet. You want the well driven into the water table far enough that the entire well screen is in the water.

While a driven well may not produce as much water as a drilled well, it should be able to produce five gallons per minute of water flow. Connect a pump to the well and see how much water you can get out of it. If it isn’t producing enough, remove the pump, reattach the cap and drive it in a bit further.

At first, your well water will be muddy, but it shouldn’t take long for it to produce clear, clean water. Be sure to connect a check valve below the pump, to prevent the water from going back down into the well. It’s a good idea to have your water tested before using it extensively.

Drilled Wells

Although most well drilling rigs are intended for use by professionals, it is possible to use them yourself to drill your own well. Some rental companies do provide well-drilling rigs for rent, but they are rather rare. However, there is one option for drilling your own well, which is affordable and possible to do yourself.

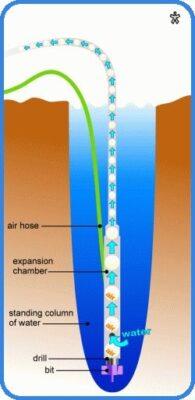

On the website www.howtodrillawell.com, you can buy a kit for drilling your own well. This kit uses air power to drive an air motor which is down the hole in the well, directly behind the drill bit. While a totally different concept than other well drilling methods, it is quite effective.

Drilling your own 100-foot deep well will cost you about $1,200, not counting the cost of the well pump. The kit available from that website will account for about half of that cost, with the other required materials accounting for the other half. The kit includes an instruction video and booklet, with detailed instructions for drilling your own well.

There is a lot of preparation in drilling a well in this manner. Once again, you start with a starter hole that is made by a post hole digger. In addition, you’ll need to dig a small pool of water, as the well hole has to remain filled with water. This water acts both to cool the drill and motor, as well as to pump the mud back up to the surface for disposal. Without removing the mud, you’ll just end up with a drill stuck down in the ground, without a hole.

To use this air-driven drill, you’ll need to rent an air compressor which is capable of providing at least 16 CFM of air at 90 PSI. The air drives the motor, which in turn drives the drill bit. Expended air acts as the pump to bring the mud back up a one inch PVC pipe, which is attached to the drill motor.

Diagram courtesy of www.howtodrillawell.com

Drilling a well in this manner is time consuming. To put down a 100-foot well will probably take a couple of days. The exact time depends upon the type of soil you have at your home. However, the finished well will probably produce better quality water than a driven well will.

Once the hole for the well is drilled, it has to be cased. This simply means putting a four inch diameter pipe down the hole to be the well. The first section of pipe is perforated to function as a well screen. A well point is placed on the end of this, to plug the end and guide the pipe through the hole, keeping the well screen from striking the bottom of the hole. The space around the pipe is filled in with pea gravel, with a cement cap to keep debris out of the well hole.

This sort of well requires an in-ground pump, as an above ground pump won’t be able to pull water up from 100 feet below the surface. These pumps are designed to fit inside of the four inch plastic pipe which is used as the well casing. This type of pump is electric, so will require electrical power to be brought out to the well site.

Just like with the driven well, the first 100 gallons or so of water to come out of the well will probably be muddy. This is normal, but you will see it become gradually clearer. Be sure to have the water checked for purity before using.

Off The Grid News Better Ideas For Off The Grid Living

Off The Grid News Better Ideas For Off The Grid Living